Alderon Flex Power Pak Duplex Time Dose & Demand Dose Smart Control Panel (120/230V, 0-15FLA)

PrintCLEAR DOOR, POWER RELAY INSTEAD OF MOTOR CONTACTOR

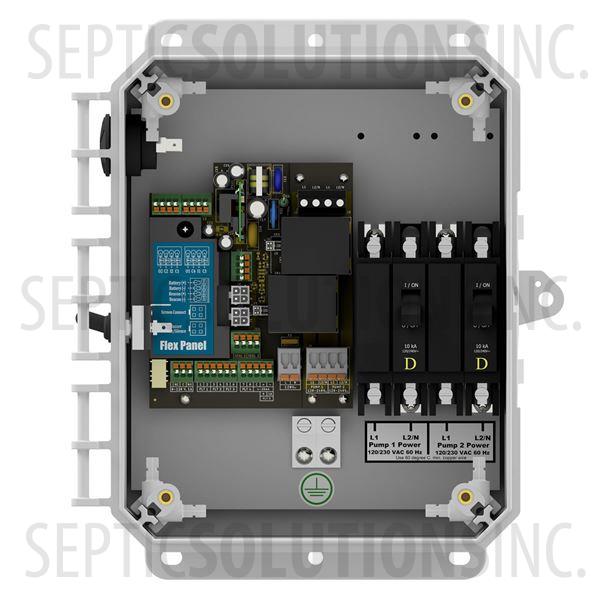

The Alderon Flex Power Pak Duplex control panel is designed to control and monitor a lift station with two submersible pumps using either demand dose or timed dose functionality. The Flex Panel includes pump circuitry, high water alarm, and 3 mechanical float switches the can be programmed to your desired functionality.

The Alderon Flex panels feature a revolutionary menu system that enables maximum field configuration and statistics tracking. A convenient setup wizard is included in the menu to get the panel configured to your desired functionality in a few simple steps. The Alderon Flex Power Pak utilizes a Power Relay to start and stop the pump instead of a motor contactor.

In Stock

Item #:2010697

Manufacturer: Alderon

Ships Monday

with FREE SHIPPING

Order in the next: -- hr --min --sec

Ship Date Mon, Mar 9

Delivery: 1-4 Business Days

FLEX POWER PAK DUPLEX SPECIFICATIONS

- Controls Two Submersible Pumps at 120/230VAC, Single Phase, 0-15 FLA

- 120/230VAC Power Input for Pumps, 120VAC Power Input for Alarm/Control Circuit

- Includes (3) Mechanical Floats w/ 20ft Cords

- Demand Dose Float Functions: Off, Lead On, Lag On, Alarm

- Timed Dose Float Functions: Low Alarm / Redundant Off, Timer Enable, Peak Timer, High Alarm

- Automatically Alternates Pumps Each Cycle

- Clear Door - View LED Screen and Multi LED Alarms and Status Indicators

- Programmable for Time Dosing or Demand Dosing

- Advanced Menu System to Maximum Field Configuration Options

- Simple Setup Wizard in the Menu, Configures in minutes!

- High decibel alarm buzzer (100 dB)

- Pump Hand/Off/Auto Toggle with Indicator Light

- Exterior Test Toggle Switch to Test Alarm and Quick View Pump/Alarm Statistics

- Field wiring terminal strips

- Conformal Coated Circuit Boards for Reliable Thermal and Moisture Protection

- Built-In Printed Circuit Board Surge Protection

- Power Relay Instead of IEC Motor Contactor (100,000 cycle rating)

- Motor Circuit Breaker

- Automatic Resettable Alarm and Control Fuses

- Auxiliary Dry Contacts - NO/NC activated by General Alarm or Power Loss

- Pad-Lockable NEMA 4X Enclosure, UL 508A Listed

- Dimensions: 10.00'' W x 11.25'' T x 5.00'' D

- Three Year Manufacturer's Warranty

FLEX POWER PAK DUPLEX ADVANCED FEATURES

- Easily Change Configurations

- Advanced Pump Station Statistic Tracking

- Pump Elapsed Time

- Min/Max/Avg Pump Run Times

- Pump Cycle Counter

- Total Gallons Pumped

- High Level Stats

- Many More

- Multi-Color Super Bright LED Light Strip

- Green = Normal

- Red = Alarm

- Blue = Pump Run

- Red/Yell = Sensor Error

- Many More

- Multiple Sensor Options

- Field accepts up to 5 Float Inputs to Allow for Low Alarm and Auxiliary Switch Options

- Configure Float, Auxiliary or 4- 20 mA Submersible Transducer

FLEX DUPLEX PANEL APPLICATIONS

- NEMA 4X Enclosure for Outdoor Installations

- Used to control a pump station with a two submersible pumps

- Time Dosing Controller allows for scheduled dosing and flow equalization

- Programmable Smart Controller includes Elapsed Time Meter and Cycle Counter

- Programmable Smart Controller keeps record of Time Overrides and High Water Alarms

WHY USE TIME DOSING?

Time Dosing control panels are used to control the amount of water a submersible pump can push to the secondary system over a period of time. The Simplex and Duplex control panels listed above are considered On Demand or Demand Dose systems. This means the pump will run when it needs to based upon the float switch in the tank. Time Dosing or Timed Dose panels use a Repeat Cycle timer in which an ON cycle and an OFF cycle is set for the pump and the timer follows that cycle repeatedly.

The reason for time dosing is to equalize the flow of water to the secondary system. In certain applications large amounts of water can be used in a short period of time. This is very hard on a septic system. With a Time Dosing control panel, you can equalize that flow by spreading it out throughout a longer period of time. The Repeat Cycle Timer will dose the system by running the pump short periods of time throughout the day versus an On Demand system (like the Simplex and Duplex Panels Above) that will pump a large amount of water all at once.

Our Time Dosing Control Panels are available in 120V and 230V. We have them for both Simplex and Duplex applications.

Alderon Flex Power Pak Duplex Time or Demand Dose Control Panel Videos

Products Other Customers Were Interested In:

- Cajun Aire Alternative 750 GPD Piston Septic Air Pump

Item #:CA750M

Our Price: $525.00MSRP: $555.00Free ShippingView Product - Septic Air Pump Alarm Panel

Low Pressure Alarm for Air Pumps

Item #:50B135

Product VideoOur Price: $172.50MSRP: $195.00Free ShippingView Product - Multi-Tite 2'' Rubber Grommet Pipe Gasket

Works With SCH 35 and SCH 40 PVC

Item #:GR-2MT

Our Price: $9.50MSRP: $16.95Free ShippingView Product - Clearstream Replacement Diffuser

Item #:N750CF

Our Price: $25.00MSRP: $35.00Free ShippingView Product - SPI Model SDC12B Duplex Control Panel with Elapsed Time Meters

120/230 VAC, 0-20 FLA, ETM for Pumps

Item #:50A506-C1-C4

Our Price: $1225.00MSRP: $1499.00Free ShippingView Product - SPI Duplex Time Dosing Control Panel

120/230 VAC, 0-20 FLA, Analog Timer

Item #:50A810

Our Price: $1660.00MSRP: $1999.00Free ShippingView Product - Alderon Altra Control Switch with 10' Cord

5 Amps, Mechanical, Normally Open

Item #:2001054

Our Price: $49.00MSRP: $65.00Free ShippingView Product